Doppler ultrasonic flowmeter flow in open channel

Products overview:

ZW - LDN - 500 n seriesDoppler flowSound waves flowmeterThe velocity, water level and temperature measuring instrument is an integrated system, using ultrasonic doppler principle, in rivers, streams, and large pipe flow in open channel, measuring water flow velocity and water depth.Instrument is suitable for the discharge of sewage and waste water, clean streams, drinking water, and even related parameters measured in seawater.Instruments measure the forward and reverse flow state, and can be programmed calculation in the pipeline and open channel flow and traffic.Each part name is as follows: the probe output terminal communication cable input cable tieline charger.

Probe the front two circular device for ultrasonic transmitting and receiving device, shall not be pinched or a collision with good thing when install and use the shielding removed;Mesh round hole at the bottom of the built-in pressure sensor, can not to contact with thin hard objects, when install and use the protection film peel;The two wings of the four holes for mounting holes, with M6 stainless steel screws and the base is fixed.

Second, the working principle:

ZW - LDN - 500 n seriesDoppler flowSound waves flowmeterProducts have three functions: average flow velocity, water depth, water temperature measurement.

1, water temperature measurement, including water temperature measurement using temperature sensor, temperature sensor does not contact with water, close to the instrument at the top of the packaging materials, placed in the bottom after a certain period of time is needed to reflect the actual water temperature.Measure water temperature correction is the purpose of the speed of ultrasonic wave in the water, and correct the water level value of measured by pressure sensor.

2, water depth measurement (area of water) : water depth measurement using imported high precision pressure sensor, placed at the bottom of the instrument, the probe sensor parts in direct contact with water;After water depth measured, cross section shape can be obtained through the channel section area of water.

3, average flow velocity measurement, the measurement of flow velocity is by ultrasonic probe (transducer) is the transmission and reception super living wave signal and do the corresponding processing and obtain: 1 emission transducer frequency ultrasonic signal for f1, at an Angle from the underwater to surface launched, after the encounter the suspended particles in the water or air bubbles, the frequency offset, and f2 reflect the frequency of the transducer

On 4, this is doppler, f2 and f1 is the difference between the multiple spectrum, frequency offset fd.Set the fluid velocity v, ultrasonic sound velocity for c, doppler frequency shift fd is proportional to the fluid velocity v.Will have a lot of impurity particles and bubbles in water, each reflection particles corresponding to a doppler frequency shift fd, through the conversion can be obtained by its velocity, the large number of particles mean velocity and the average flow velocity of the fluid.

Through the measured average flow velocity and water level and section size, cross section flow can be obtained.

Three, the main features:

ZW - LDN - 500 n seriesDoppler flowSound waves flowmeterCompared with similar foreign products, under the premise of the same performance, in addition to the highly price advantage, has the following advantages: supporting terminal (with the standard output interface), Chinese user interface, small power consumption, a looming large storage capacity.Is widely used to replace the existing water flowmeter and ultrasonic flowmeter ideal products.

Doppler ultrasonic open channel flow meter compared with the method of water flow meter:

1, no head loss and does not need construction slot or weir

Does not need to rate constant water flow curve, especially applicable to water method cannot measure flow channel;Do not need to engineering construction, engineering cost, installation is simple and does not need to stop quickly.

2, installation is simple and needs no water Wells and other auxiliary engineering facilities

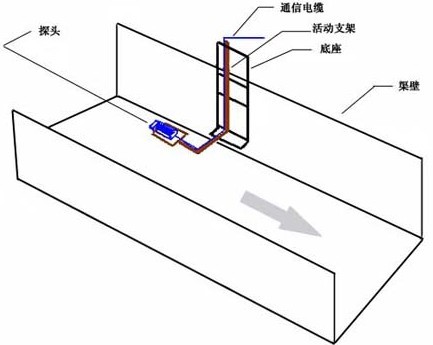

Instrument probe part installed directly on the fixed channel walls easy removable at the bottom of the bracket, and through the communication cable and in management room (or tiny workshop) control terminal (with functions of control, display, storage) connection.

3, low power consumption, without external power supply can field work continuously

Control terminal with small battery can work continuously for two months, after the replacement spare battery charging or can work continuously, can also be an external battery or domestic load.

4, field display, storage, storage capacity can be up to six months

On-site automatic display zui after a test data, and can also be used on the terminal display control button on the historical data;10 minutes measurement data can be stored for half a year at a time.

5, measuring flow, water level, flow velocity, water temperature at the same time

Water level accuracy can reach 1%, the velocity accuracy can reach 2%

6, the standard output interface

GPRS, GSM communication module can be directly used for data remote transmission, can through the remote communication equipment to measure the data transmission and the timing of measurement, can also be used for remote parameter setting (such as measuring the time interval, time transmission interval

Doppler ultrasonic flowmeter and the ultrasonic time difference method of open channel flow meter compared:

1, the measuring accuracy is not affected by water level change, do not need multiple sets of probe

Ultrasonic time difference method is required for a flowmeter in channel water level changes greatly in different height are placed between the probe and measuring error changes over water, the calibration accuracy of measurement generally refers to an ideal level of accuracy, when the water level change actual measurement error will be larger;

2, low power consumption, built-in battery (rechargeable) can work for two months

Ultrasonic time difference method flowmeter general need ac power supply;

3, can be used as a portable meter

Only when the measure would probe exile under level into the bottom of the channel;

4, installation is simple

Don't need to be on both sides of direction, fixed to the specified location;

5, the price advantage is obvious

Is the existing ultrasonic time difference method flowmeter 1/6 of the price.

Can be used as a portable meter.

Only when the measure would probe exile under level into the bottom of the channel;

6, installation is simple

Don't need to be on both sides of direction, fixed to the specified location;

7, the price advantage is obvious

Is the existing ultrasonic time difference method meter price 1/6 ~ 1/3.

Fourth, conditions of use:

The water quality requirements:

Some tiny impurities or bubble water, the water floater not easy too much.

1, when too much water floater and use the instrument, weeds or plastic bags may cover the probe and make the work of the failure, then need to work in the instrument when not in normal clear the mulch on the probe in a timely manner.Trash rack can be installed at the upstream when conditions permit, but trash rack distance from the instrument not less than five times the hydraulic radius, lest the aquatic plants such as sedimentation in front of trash rack can cause unstable flow regime, at this time in front of the trash rack debris to be cleared on a regular basis.(when the too much clutter and jamming equipment such as aquatic plants, need to deal with the measured results, will remove the interference of the data, the concrete can be implemented by software or artificial;If interference serious interference data processing need experienced professionals to do).

2, when the water reaches the secondary drinking water, choose there are air bubbles (e.g., drop or downstream of the gate is a certain distance) were measured.When there are air bubbles in the flow instability do not conform to the requirements of the current flow of the steady flow and fail to adopt effective measures, such as setting rectifier gate or steady flow plate), then can only choose to smooth flow section measurement and adopts the following special tools:

A: as for irrigation water placed in the bottom of a measurement in the upstream channel: a certain amount of lump can keep a long time at low velocity of flow;When the velocity larger will clump washed clean, but at this point will produce bubbles in water and can satisfy the measurement requirements.So when the velocity increase and smaller, should be placed in the bottom of a upstream canal anew the clods of certain amount.

B: upstream a certain position in the measurement was set existes device to generate bubbles (such as water retaining grille, will produce certain head loss at this time, and increase in velocity that may produce turbulence) within a certain distance in the downstream.

The choice of flow section (flow) :

Flow upstream section requires ten times the hydraulic radius of straight section, five times the hydraulic radius of downstream straight section, and the rules of cross section shape stability, to ensure the installation position of the flow regime uniform stability.If the installation position of poor flow or straight section is shorter, one way is in the upstream setting rectifier gate (or steady flow cover plate) for steady flow state, at this time should be paid attention to when the water weeds too much jam rectifier gate and have the opposite effect, the solution is to clear in time for the weeds blockage rectification grid or in upstream add trash rack;Another option is to rate a correction factor or in the same place each full set 1 instrument or install the instrument in the channel in the middle position.The above two ways are will affect the precision of the instrument.

The application of sediment channel

Instrument is divided into A, B, C three kinds of models, to adapt to the different sediment concentration of water quality:

Sediment concentration choose model 6 ~ 25 kg/m3 3 ~ 6 kg/m3 type B 0 ~ 3 kg/m3 C type

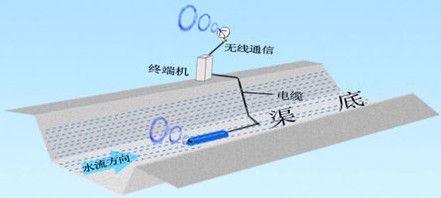

Five, the overall installation instructions:

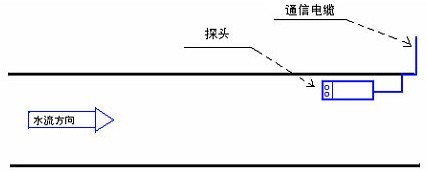

Above to install effect simulation diagram

Sixth, the installation of the probe:

1, the installation location:

In the cross section of the probe should be installed on a fixed channel straight section downstream, straight length 5 to 10 times that of channel hydraulic radius (the longer the straight section of the higher the accuracy of measurement), and the distance range can not have over-current blocking content (such as locks, weir, etc.), to ensure the uniform stability of probe front the flow regime.

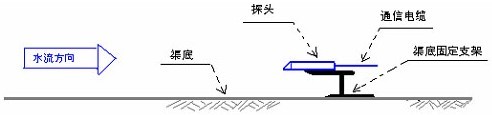

Probes should be installed on the bottom of the near the canal, when the channel bottom sediment and aquatic plants growth or rolling pebbles, can raise the installation location to avoid canal bottom sediments and aquatic plants cover probe or pebble collision probe;Specific probe from the canal bottom height is 100 mm - 250 mm, depending on the zui low flow water level of the channel.When the channel depth is higher and has certain zui low water level, in order to convenient installation as long as the probe mounted on zui under low water level to 0.5 times.

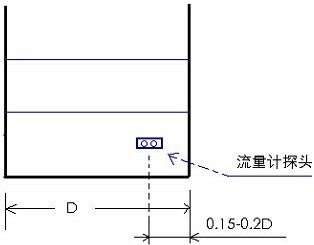

The installation position of the probe in rectangular channels

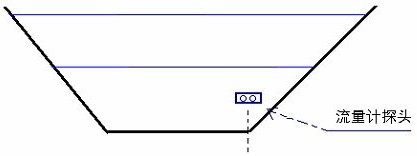

Probe installation position in channel cross-sectional area generally as follows (canal under the 20 m wide) : for rectangular installed on the channel width of 0.15-0.2 times;The trapezoidal section is installed on the slope foot;For larger width of channels, need to install two or more than two (2) of the probe, location depends on the channel width and the flow distribution on the transverse section.

The installation position of the probe in the trapezoidal cross-section channels

2, installation method:

Probe installation should be completely level on the bottom of the channel (note not level), ensure consistent with parallel in the direction of flow at the same time, probe the front-end (no one end of the communication cable) under flow direction and in the direction of flow Angle is 180 degrees, and probe the front must not have the obstacle interferes with the flow regime, communications cable from the probe of the downstream along the canal slope bottom and channel leads to the surface or from the mounting bracket of the steel pipe surface.

The probe should be completely parallel to the flow direction

Can be completely off the channels of water, can be fixed probe stent (fixed bracket can be customized in the local, and probe the connection part with stainless steel plate and bolts) directly fixed on the bottom of the channel;For not completely with water and underwater operation after the switch-off still has a higher water level upstream the inconvenience of channels, can fix the stent drainage arm.Fixed in canal arm bracket has two ways: simple stents and composition.Summary stent mainly for a degree of bending of steel pipe or zinc tube, welding level at the bottom of the steel plate with a fixed probe, erect pipe through transverse wing of the steel fixed on the canal arm;Composite scaffold is made up of base with removable parts, sensor installed on the removable part, base one-time fixed installation in the current section (by upstream temporary switch-off lower water level, after expansion bolt on concrete slope), removable parts by the bolts connected with the base fixed on the water, so to facilitate maintenance and replacement of the probe in the future.

Install the probe directly fixed on the bottom of the canal

Summary stent scene rendering

Seven, combination principle diagram:

1, communication cable installation:

Communication cable shall be made by the probe and canal wall along the bottom channel downstream direction leads to the surface, need protection and along the fixed set of PVC pipe;When using arm bracket probe, communications cable can be hollow steel tube leads to the surface along the stents.

Probe by bringing a communication cable in ventilation ducts, so pay attention to not to bend it.After the communication cable leads to the surface, but ordinary cables, ventilation duct opening direction should be brought down, and breathable fabric, prevent water and foreign matter into the ventilation tube.

After installation of fixed communication cable, need connected to terminals through turn "connection", "tieline" four core wires are: power is yellow, blue for the power supply, red is A data line, black cable B (corresponding to the communication cable wires are: red black line into the power supply is, network cable for the power supply, the two remaining roots for R485 data line A and B.).

2, the installation of the terminal:

Terminal shall be erected fixed within management room or tiny workshop, pay attention to waterproof.Terminal communication cable and probe are carrying through turn "wiring" connection;Terminal and communication device or computer connection, you need to use the "output" input cable."Output" input cable has R232 and R485 two modes, when use a laptop without a serial port to the site access, need to turn the match R232 USB connector

Eight, directions for use:

1, using the process

Installation location choice go to probe installation method to determine, cable lines and fixed way to do the mounting bracket, installation probe and cable - fixed terminal to connect tieline and communication cable, through the input output data line connection terminals and data protocol (using wireless communications) to connect wireless communication instrument source, charging power supply connection terminal charge (if online) - > terminal acquisition button, check the probe working condition to design terminal working mode, check the communications protocol working conditions to install wireless monitoring software (wireless) or laptop access software and statistics software

2, monitoring software

See CD attached with box

Monitoring software has two kinds: the scene monitoring software and wireless monitoring software, on-site monitoring software installed on the laptop, with notebook flowmeter output terminals of the standard R232 or R485 input interface is directly connected to the historical data to measure reading and terminal working parameters setting;Wireless monitoring software installed on the upper management machine, through wireless communication equipment for real-time measuring data read and terminal working parameter setting.

Nine, monitoring software mainly has the following features:

1, the management of measuring point, increased or deleted point;

2, for each measuring point terminal parameters setting;

3, read and store each measuring point measurement data;

4, the statistical analysis of measurement data query;

5, in electronic map display of observation and can just click on the diagram real-time query each measuring point measured values (wireless).

Ten, daily maintenance:

Probe maintenance, probe the front two circular ultrasonic transceiver should avoid hard hit or scratch, without soft set of protection, should be used when the application when the above attached foreign body wash or soft cloth light;Inside the hole at the bottom of the pressure sensor is located in the mesh, its pressure membrane are very temperamental, not to contact with good thing, in the instrument out of the water should be protected, when not in use around the through hole to foreign body should be removed.

Battery maintenance:

Cells in the absence of power supply should be at least one and half months to charge and discharge.

Terminal maintenance:

Terminal should be placed in a dry place, moistureproof, should be paid attention to in field conditions is wet plastic film packaging.

Eleven, matters needing attention:

Because it contains ventilation tube 1, communication cable, so can't bend over, to prevent the broken;

2, the inside of the communication cable ventilation tube and probe the inside of the circuit board are interlinked, not into the water, when installation should make the end of the vent opening downwards, prevent moisture and water along the pipe wall into the probe circuit;

3, communications cable leads to the surface by the probe should try to coat the PVC tube and fixed or along the stent tube along the line, to avoid directly produced by hydraulic shock, especially aquatic plants more channels to produce very big when hanging grass on cable tension and possibly will cable snap;

4, probe the circle in front of the super living wave transceiver can't impact and scratch;

5, after installation of the probe to the front of the ultrasonic transceiver shielding removed, and the protection of the mesh at the bottom of the round hole in the paster peel;

F terminals and probe connections must be correct, otherwise it will result in instrument damage.

6, instrument probe should avoid long time exposure in the sun, in order to avoid high temperature caused by the fault (probe temperature shall not exceed 70 ℃).

Twelve, parameter table:

The velocity range | 21mm/sto5000mm/s |

Accuracy of measurement | Measuring the velocity ofPlus or minus 2% |

points bianThe rate of | 1mm/s |

The temperature range | 0℃ to60℃ |

The water level range | 0to5m |

Accuracy of measurement | Measuring water level ofPlus or minus 1% |

points bianThe rate of | Resolution:1 mm |

forelectricity | Inside the battery6V DCThe external6VDC~28V DC |

The environment temperature | 0℃ to60℃ temperature |

tong The letter | standardRS232、RS485 |

Data storage | every10Minutes to collect a record, can store more than6A month of data, and these data even in the case of power lost, also can not lose for a long time |

The probe cable | Can be up to100M, the standard10m |

' " | (230 * 83 * 30)mm(The probe) |

13, design selection and ordering information:

1, products: specify model standard, if any, please live in wei sales hotline advisory prices, details!

2, technical support, if not specified product specifications, please put the working condition of requirements, design drawings, technical specifications, fax or email to us.

3, product orders for parameters: size (DN), nominal pressure (Mpa), temperature (℃), the connection way (flange, etc.) to the clamp.

4, offer confirmation: the company provide price list and technical standard specifications to customers to confirm, in the technical aspects to confirm before you draw up a contract.

5, quality requirements, quality standards, the supplier is responsible for the quality conditions: according to the relevant state quality standards.

After-sales service commitment:

1, from the date of signing of the contract, I in the way provided for products of the company offers free maintenance and maintenance service, commitment to lifelong maintenance service;

2, jiangsu wei measurement and control instrument co., LTD. Sales manager will be in regular contact with customers, understand the usage of products, and solve the problems of the customers to use in the process of produce, free of charge to provide technical support;

3 the man-made damage is found, the warranty period, our company is responsible for the maintenance, and the resulting maintenance fee;

4, product quality problems or are not satisfied with product, the user can choose unconditional return, wei tt&c don't charge any fees, appear quality problem, bear the freight back and forth.