Fixed flange radar liquid level gauge

Products overview:

ZWRD905 seriesFixed flange radar liquid level gaugeBy microwave pulse measurement method, and can be within the scope of industrial frequency band is normal, low beam energy, can be installed on a variety of metals, non-metallic, container or the pipe for liquid, paste, and granular material level for non-contact continuous measurement.Applicable to the dust, change of temperature, pressure, and presence of inert gas and steam.No harm to human body and environment, let the customer buy intelligent radar level meter to buy the rest assured, worth to buy.High frequency microwave pulse by transmitting and receiving antenna system, radar wave running at the speed of light, running time can be transformed into material level signal by electronic parts.A special type of time extension method can guarantee the stability of a very short period of time and accurate measurement.

Second, the working principle:

ZWRD905 series fixed flange radar level meter is the measuring instrument based on the principle of time travel, very low energy is emitted by a very short microwave pulse by transmitting and receiving antenna system.Radar wave are running at the speed of light.Running time can be transformed into material level signal by electronic parts.Probe a high-frequency pulse and probe the conduction along the cable type or rod type, when the pulse in the material surface reflected by the receiver inside the instrument, and the distance signal is transformed into material level signal.A special type of time extension method can guarantee the stability of a very short period of time and accurate measurement.Even if the condition is relatively complex, false echo, with a new micro processing technology and debug software can accurately analyze the level of the echo.

The input

Antenna receiving the reflected microwave pulse and sending them to the electronic circuit, microprocessor to signal processing, identify the micro pulse produced by the echo in the material surface.Correct echo signal recognition completed by intelligence software, precision can reach millimeter level.Distance on the surface of the material distance D is proportional to the pulse travel time T:

D=C×T/2

Where C is the speed of light

E known due to empty cans of distance, the level of L as follows:

L=E-D

The output

By entering empty cans height E (= zero), full tank height F (= full scale) and some applications to set parameters, application parameters will be automatically adapt instrument to measure the environment.Corresponding to the 4-20 ma output.

Applications:

ZWRD905 series fixed flange of radar level gauge is suitable for liquid, paste, and granular material a non-contact continuous measurement, and the change of temperature, pressure, and presence of inert gas and volatile situations.Using microwave pulse measurement method, and can be within the scope of industrial frequency band to work normally.Beam energy is low, can be installed in all kinds of metal, non-metallic vessel or pipe, no damage to the human body and the environment.

Four, the application of medium:

Electricity plant, coal, raw coal, fuel storage, reservoir, exhaust gas purification tank, pump, ash library, tank, etc.;

Oil fields: crude oil or refined petroleum products storage tanks, three-phase separator, sedimentation tank, sewage tank, oil-water interface and drilling mud tank, etc.

Work: the crude distillation tower, raw material and intermediate bunker tank, reaction tank, ammonia, solid bin, separator, etc.;

Kim: smelting ore bin, ore mill, raw material warehouse, accessories warehouse, blast furnace, alumina powder storehouse, electrolytic cell buffer tank, etc.;

The water mud, stone warehouse, pulverized coal bunker, cement warehouse, warehouse, slag storage warehouse, etc.;

Water treatment: reservoirs, sewage pool, cans, sedimentation tank, deep well water treatment, drinking water network, etc.;

Made of paper: raw materials warehouse, towers, drum drying, chemical storage materials storage warehouse, etc.;

He: its quarry, food, pharmaceutical, environmental protection, shipbuilding and other industries.

Five, the main features:

1, the beam Angle is small, the energy concentration, for radar installation location has more flexibility.Have stronger anti-interference ability, greatly improve the measurement precision and stability.

2, small antenna size, convenient for radar installation, at the same time for small tanks and tanks special measurement has a better adaptability.

3, the measuring blind area small, big z limit increases the radar measurement range.

4, shorter wavelength for powder, granular materials such as measure effect is better.

5, launch the pulse signal, transmission power radar level meter is extremely low, can be installed in all kinds of metal and nonmetal container, no harm to human body and environment.

Six, the technical parameters:

1, application: solid storage containers, containers or strong dust easily crystallized, condensation occasions;

2, measuring range: 70 m;

3, measuring accuracy: + / - 15 mm;

4: (- 40 ~ 80 ℃), process temperature (40 ~ 130 ℃ (60 ~ 250 ℃) (60 ~ 400 ℃).

5, frequency: 26 GHZ;

6, the signal output (4 ~ 20 ma), HART, Modbus;

Two wire system, power supply, 24 v, 24 v / 220 v; four wire

8, field showed that the standard;

9, shell, selection;

10, process connection: thread/flange;

11, antenna: the horn (316 l stainless steel).

Seven, the debugging methods:

A, can through debugging in three ways:

1, by displaying the adjustment module PM;

2, through debugging software SOFT;

3, handheld programmer by HART.

B, through SOFT software debugging:

No matter the signal output, 4-20 ma/HART, radar sensors can be through the software debugging.Is instrument with the SOFT software debugging, need a meter CONNECTCAT drives.

Using software debugging, for the radar instrument 24 VDC power up, at the same time connect HART adapter front end with a resistance of 250 ohms.If the one-piece HART resistance (250 ohm internal resistance) of electricity meter, there is no need for additional external resistance, HART adapter can and 4...20 ma line in parallel.

Eight, daily check the maintenance:

1, daily inspection maintenance mainly to check the power supply voltage and output current is normal.About 30 ~ 60 min after electrify, instrument can work normally.If there is no output parameter meter, should check whether the power supply is connected to real, and check whether the fuse is burnt.

2, when using is become an organic whole repeatedly and equipment, the whole system radar level meter is sealed, so at ordinary times should also check the sealing condition of joints of different parts are in good condition.

3, radar, head of the use of the internal temperature of 65 ℃.General use cases not more than the temperature, but if the temperature of the measured medium is very high, is the temperature inside the radar head could exceed 65 ℃.At this time, can use a small amount of wind, by the phi 6 x1 copper tube rain hat head blow in radar, to internal temperature down, never to do mechanical cooling water or other liquid.

4, volatile organic compounds in crystallization or antenna, radar level gauge trumpet to timely inspection and cleaning.

Nine, environmental impact factors are:

1, the influence of the obstacles.

If the launch of the electromagnetic wave instrument comes into contact with the barrier, then you'll get a jamming waveform.If you can't choose other ideal installation location, choose the small beam Angle instrument or using guided wave tube and by-pass pipe installations can be solve the problem.

2, the influence of the transmission medium

(1) the temperature;

(2) pressure;

(3) the transmission medium corrosion resistance;

(4) whether the transmission medium contains steam or dust, etc.;

(5) the volatiles in the environment with crystallization or dust adhesion problems.

To solve the above problem, then we will guarantee, electromagnetic waves or ultrasonic arrived in material surface under test, no big attenuation.Measured on the surface of the material through reflection, get a echo signal.The strength of the echo signal and the measured material surface under state.

1, the dielectric constant of the measured substance or hardness.

The strength of the dielectric constant influence the electromagnetic wave reflection.The echo of the dielectric constant, the greater the stronger.While the hardness is reflection of sound waves.The greater the hardness, the stronger the sound wave reflection.

2, on the surface of the material being tested pile Angle;

3, on the surface of the material being tested stability;

4, particle degree of the measured object and loose;

The analyte 5, moist degree.

Ten, the matters needing attention:

1, measurement range from the beam hitting a can of low starting point, but under special circumstances, if the tank is low for concave type or conical, when the level below this point cannot be measured.

2, if the medium to low dielectric constant when it is in low level, low visibility, at this time in order to ensure the accuracy of measurement, the recommendations will be zero at low altitude to the position of the C.

3, theory, measurement to achieve the position of the antenna tip is possible, but considering the corrosion and the influence of the adhesive, the final value of measuring range should be at least 100 mm distance from the tip of the antenna.

4, the overflow protection, additional on the blind spot can define a safe distance.

5, measurement range related to the antenna.

6, with different concentration, foam can absorb microwaves, and it can be reflected, but under certain conditions can be measured.

7, measurement is beyond the scope of action when the measuring range beyond, instrument of 22 ma current output.

Eleven, parameter table:

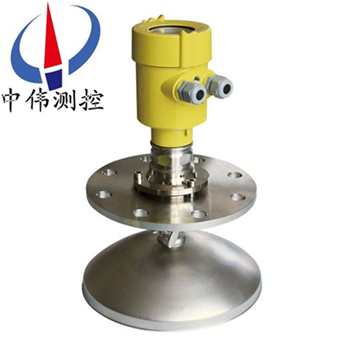

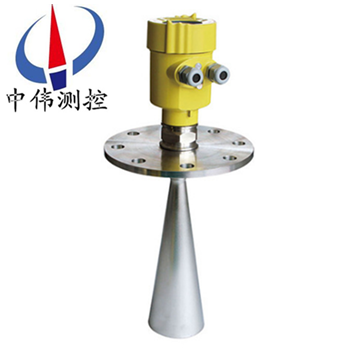

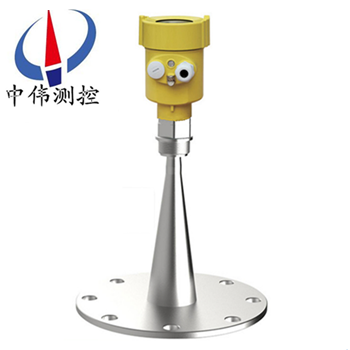

Product category | ZWRD904 | ZWRD905 | ZWRD906 |

Product pictures |  |  |  |

Range of application | Process conditions of simple, solid blocks Strong material, dust environment such as: | Solid block, particle material | Health or strong corrosive liquid |

measuring The amount van wai | 70m | 20M optional | 30m |

pass cheng evenPick up | Thread, universal flange | Thread, flange | Thread, flange |

pass cheng wenThe degree of | - 40-250℃ | - 40-250℃ | - 40-250℃ |

pass chengpressure force | -1.0-3bar | -1.0-20bar | -1.0-40bar |

heavy after sex | ± 3mm | ± 3mm | ± 3mm |

fine The degree of | < 0.1% | < 0.1% | < 0.1% |

frequency The rate of van wai | 26GHz | 26GHz | 26GHz |

explosion-proof/Protection grade | EXiaIICT6/IP68 | EXiaIICT6/IP68 | EXiaIICT6/IP68 |

The letter No.Lose, Out of the | 4…20mA/HART(The two lines) | 4…20mA/HARTTwo lines) | 4…20mA/HART(The two lines) |